Cooperation with Faspar

FASPAR designs and manufactures turn-key lines for coil processing for ferrous and non-ferrous metals (stainless steel, aluminium, titanium, copper, brass, pre-painted, tin-plate, steel, galvanized, high tensile strength and electric steel). Each product is highly customized and supplied on the basis of tailor-made solutions.

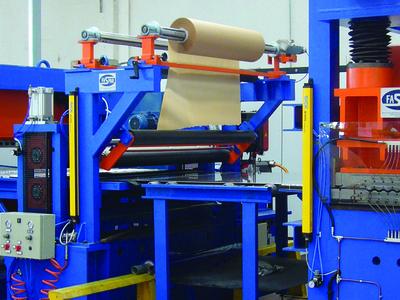

FASPAR’s production range consists of coil processing equipment, such as slitting lines, packaging lines, robots for automatic handling of cutters and spacers for slitting lines, levelling and cut-to-length lines, surface finishing lines, embossing lines, tension-levelling lines and single special machines and lines.

In addition to the above-mentioned products, FASPAR also offers several services, such as after-sale service and teleservice, spare parts supplying and replacement, revamping and retrofitting both on FASPAR lines and on any other coil processing line brand.

FASPAR’s mission is supplying customers with best-for-value coil processing equipment, meeting customers’ requirements, needs and expectations. FASPAR invests intensively in R&D and launches innovative products in order to meet the most up-to-date market requirements with professionalism and customized solutions.

FASPAR is a worldwide excellence brand in machine building thanks to its 50-year experience, with well over 300 lines having being installed everywhere in the world (in particular in Europe, Central and South America and India). It is well-recognized as a synonym of advanced know-how and engineering skills.

FASPAR is a well-known coil processing lines manufacturer in several market segments, such as automotive, white goods, construction, can-making, packaging, decoration and many others. It also serves the primary industry and the most important service centres, which process ferrous and non-ferrous materials, electric steel and tinplate.

PRODUCTION RANGE:

• LEVELING AND CUT-TO-LENGTH LINES

Faspar designs and manufactures levelling and cut to length lines for carbon steel, stainless steel, electric steel, tin-plate, aluminium, copper and all kind of non-ferrous material from hot rolling, cold rolling, pre-painted, annealed, thermal treated, etc.

Faspar’s lines excel in levelling technology and equips its lines with all kind of shears (drum, rotary, flying, etc.) and stacker (air cushion, bomb doors, magnetic, vacuum, etc.) as well as all kind of optional devices such as trimming shears with scrap baller or chopper, paper recoiler, paper and PVC applicators, centring units, flatness control systems, gauging and inspection devices.

Width from 300 to 2800 mm

Thickness from 0,12 to 15 mm

Coils capacity from 5 to 40 tons

Productivity up to 200 sheet/min

• SLITTING AND PACKAGING LINES

Faspar designs and manufactures high precision and high-speed slitting lines to cut mother coils into narrower coils for carbon steel, stainless steel, electric steel, tin plate, aluminium, copper and all kind of non-ferrous materials from hot rolling, cold rolling, pre-painted, annealed, thermal treated, etc.

Faspar’s lines are equipped with high precision shears with blades and spacers quick changing and positioning devices, (multiple) fast recoilers, scrap ballers/choppers according to the scrap-handling system desired and movable tensioning system with different technology according to the type of material.

Width from 300 to 2800 mm

Thickness from 0,12 to 15 mm

Coils capacity from 5 to 40 tons

Speed up to 600 m/min

• MULTI-BLANKING LINES

Faspar designs and manufactures versatile lines for blanks of all kinds- from very simple combined lines to their high-tech, multi-blanking and multi-shaped counterpart with several dedicated stackers (magnetic, vacuum, roller guided, etc.), levelling and tension control devices.

Width from 300 to 1500 mm

Thickness from 0,12 to 8 mm

Coils capacity from 5 to 30 tons

• SINGLE MACHINES AND SPECIAL EQUIPMENT, REVAMPING AND ASSISTANCE

Faspar designs and manufactures customised tailor made special machines and equipment catering to all sort of needs such as trimming shears, scrap choppers, embossing units, fast butt or scrapping shears, tension-levelling units, stackers, automatic separators shafts, quick tooling-changing devices, robots, loop doublers, quick levelling benches changing devices, special maintenance tools, double mandrels-turning decoilers/recoilers, packaging lines, oscillating units and all kind of new solutions developed together with our Customers.

FASPAR offers support and management of parts, exchange units, replacement of spare parts, repairing, revamping and retrofitting services. In addition to that, it offers professional customer care assistance, maintenance and training services.

FASPAR’s experienced technologists can assist its Customers in developing new products to meet ever-higher market standards by training the devoted Operators in optimising line potentialities according to desired product types.

Faspar is also highly specialised in revamping, retrofitting, increasing performances and productivity of existing old lines by recertifying them with the new EU and safety norms.

Contact in English, Polish, Ukrainian.